Ewan Wills

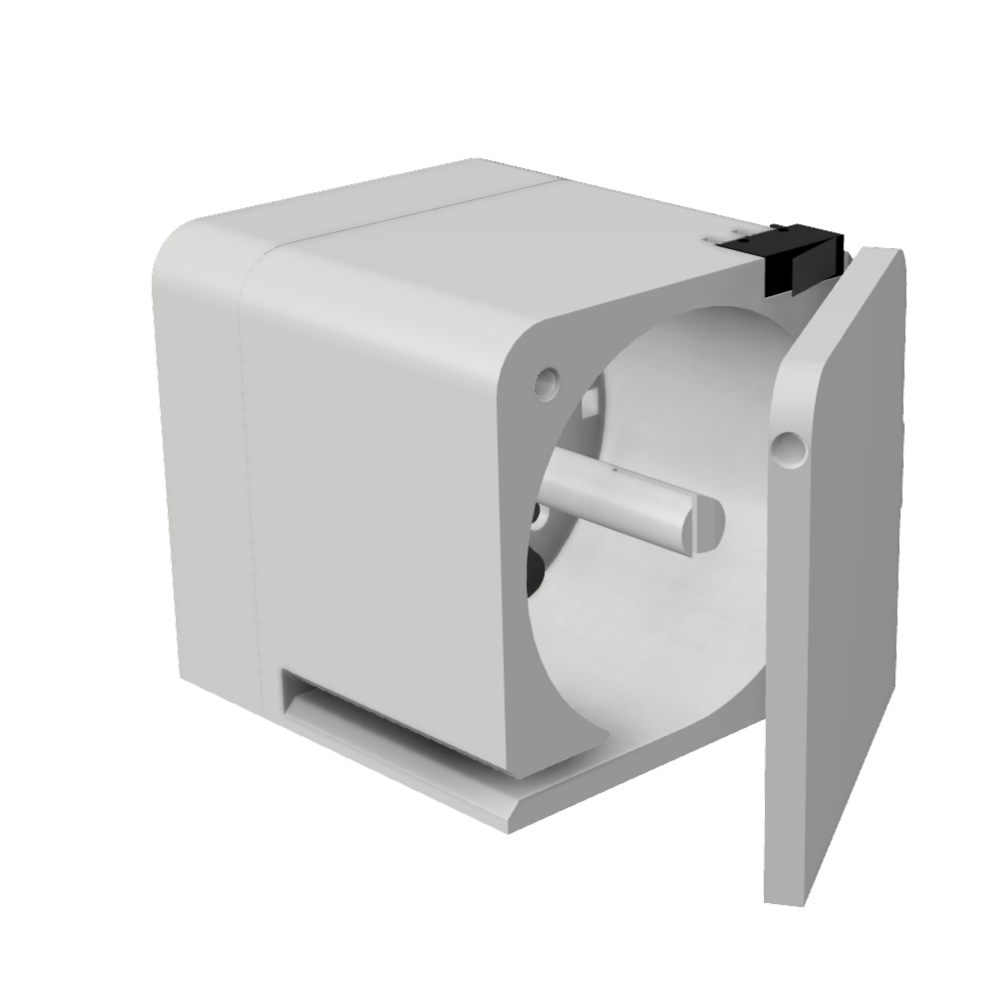

The MiniCapper is a standalone device to cap and decap vials for use in laboratory automation.

The project was progressed from initial concept through to a final version, tested in a laboratory

environment.

The system was designed for manufacturability and ease of assembly, with all custom components manufactured

from machined metal.

The EWatch is a programmable smartwatch intended for hobbyists and developers.

The project is currently in development, with availability for pre-order.

This project predominantly involved electronics design, with a strong emphasis on low power consumption and

miniaturisation.

Mechanical considerations include ergonomics, aesthetics, and machinability.

The EWrapper is a device designed to autonomously wrap combat

sports hand wraps.

The project originated from a clearly identified pain point and was progressed to market on a small

scale.

The design is optimised for speed and ergonomics; aesthetics and manufacturability were not primary

considerations, as the product was produced via small-scale 3D printing.

Custom mouthguard cases allow clear distinction

between

otherwise indistinguishable products.

The project was started with a pain point and progressed to market.

I'm Ewan Wills and I'm a product developer with a background in robotics engineering.

What is product development, you may ask? It's how I take your ideas to manufacture so you can take them to

your industry.

I specialise in robotics and design for manufacture. Along with some business knowledge, I can bridge that gap

between founders and manufacturers.

My clients typically come to me when they are looking to prove a concept prior to funding or trying to develop

a prototype into a manufacturable product.

Currently, I’m looking to expand my clientele by speaking to founders and startups.

So if you have an idea or concept you are looking to develop further, get in touch through the contact form

below.